A self-tapping screw is a screw that can tap its own hole as it is driven into the material. Self-tapping screws are commonly used in metal, wood, and plastic materials to create their own threads while being driven in.

These screws are designed with a sharp point and threads to cut into the material effectively. They eliminate the need for pre-drilling and are suitable for applications where creating a new hole is necessary. The ability of self-tapping screws to tap their own holes during installation makes them a versatile and convenient choice for various construction and assembly projects.

Whether it’s for industrial applications or DIY projects, self-tapping screws offer efficiency and reliability in fastening different materials.

Credit: www.tjlituo.com

Introduction To Self Tapping Screws

A self-tapping screw is a type of screw that can create its own hole as it is driven into the material. This type of screw is often used in metal, wood, and plastic materials due to its sharp point and threads, which act like knives cutting into the medium.

The Basics Of Self Tapping Screws

A self-tapping screw creates its own hole as it is driven into the material. They are designed to cut threads into the material, making installation easier. Self-tapping screws are commonly used in metal, wood, and plastic applications.Common Misconceptions

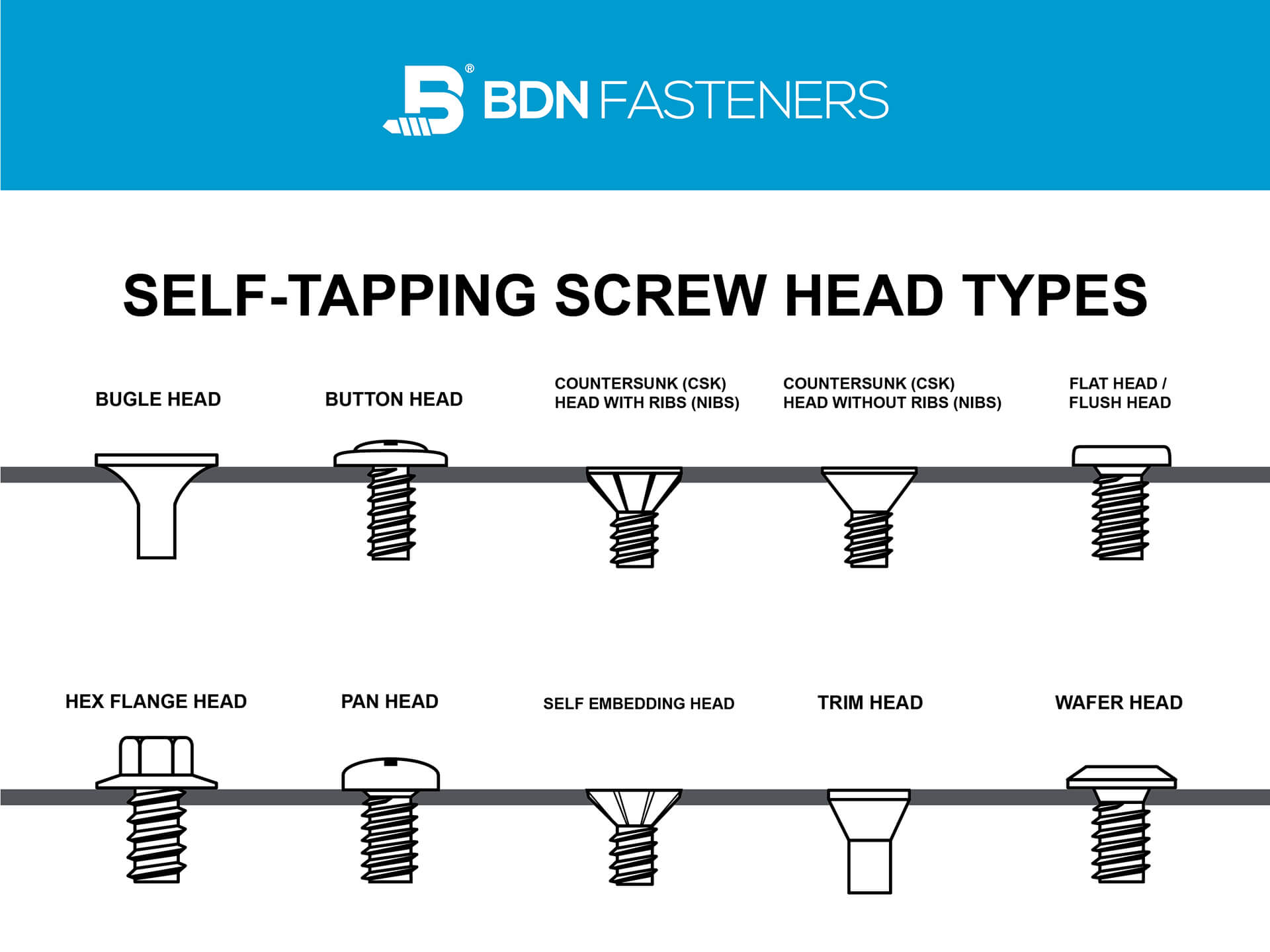

One common misconception is that self-tapping screws are only for metal. In reality, they can be used in various materials like wood and plastic. Another misconception is that pre-drilling is always necessary, but self-tapping screws can often eliminate this step.Types Of Self Tapping Screws

A self-tapping screw is designed to create its own hole as it is driven into the material, making it convenient for use in metal, wood, and plastic. With a sharp point and threads, it effectively cuts into the medium, eliminating the need for pre-drilling.

Introduction:Self-tapping screws are an incredibly useful type of fastener that can drill and tap its own hole as it is driven into the material. They are typically used in materials like metals, plastics, and wood. In this article, we will focus on the different types of self-tapping screws, specifically thread-cutting screws and thread-forming screws.H3: Thread-Cutting ScrewsThread-cutting screws are designed to produce threads in relatively soft or thin materials, such as sheet metal or plastic. These screws have a sharp point and sharp threads that act like knives, cutting into the material as the screw is driven in. Thread-cutting screws come in different types, including Type F, Type 1, and Type 23.Type F thread-cutting screws have widely spaced threads and are ideal for use in softer materials. They have a blunt point and a medium-depth thread that allows for a secure grip without damaging the material.Type 1 thread-cutting screws have a sharp point and a coarser thread than Type F screws. They are designed for use in materials that are slightly harder, like aluminum, and can be used in thicker materials.Type 23 thread-cutting screws have a finer thread than Type F and Type 1 screws. They are designed for use in harder materials, like stainless steel, and can be used in thicker materials.H3: Thread-Forming ScrewsThread-forming screws, on the other hand, do not cut into the material but instead form threads by displacing the material around the screw. These screws are typically used in materials like thermoplastics, where cutting threads can cause damage.Thread-forming screws come in different types, including Type C, Type CA, and Type B.Type C thread-forming screws have a blunt point and a shallow thread that is designed to form threads in materials like nylon or polycarbonate.Type CA thread-forming screws are similar to Type C screws but have a sharper point and a deeper thread. They are designed for use in materials like ABS or PVC.Type B thread-forming screws have a sharp point and a deep thread that is designed to form threads in harder materials like aluminum or brass.Conclusion:Self-tapping screws come in different types, each designed for specific materials and applications. By understanding the different types of self-tapping screws, you can choose the right screw for your specific project and ensure a secure and long-lasting connection.How Self Tapping Screws Work

A self-tapping screw is a type of screw that can create its own hole as it is driven into the material. This ability to tap its own hole makes it especially useful for materials like metal, where pre-drilling a hole may be challenging. The design of self-tapping screws enables them to cut and form a mating thread as they are driven into the material, eliminating the need for a pre-tapped hole.

Creating The Pilot Hole

Self-tapping screws do not require a pre-drilled pilot hole, as they can create their own. The screw features a sharp, pointed tip that allows it to penetrate the material, and as it rotates, the threads on the screw cut into the material, forming a hole and creating the mating thread simultaneously.

The Mechanics Of Self Tapping

The mechanics of self-tapping screws are based on their unique design, featuring a sharp, pointed tip and sharp threads. As the screw is turned, the sharp point digs into the material, while the sharp threads act like knives, cutting and forming the mating thread. This process allows the screw to tap its own hole, making it efficient and convenient for various applications.

Advantages Of Using Self Tapping Screws

A self-tapping screw is a versatile and efficient fastening solution that offers several advantages over traditional screws. Here are some of the key benefits of using self-tapping screws:

Ease Of Use

Self-tapping screws are incredibly easy to use, as they eliminate the need for pre-drilling pilot holes. This not only saves time but also reduces the risk of thermal damage to the material. The self-tapping design allows the screw to create its own hole as it is driven into the material, making the installation process quick and straightforward.

Versatility Across Materials

One of the major advantages of self-tapping screws is their ability to work across a wide range of materials, including metal, wood, and plastic. This versatility makes them suitable for various applications, from automotive and construction to DIY projects. Whether you are working with soft or hard materials, self-tapping screws provide a reliable and secure fastening solution.

Additionally, the sharp point and threads of self-tapping screws act like knives, cutting into the material with precision, ensuring a strong and durable connection.

Self Tapping Screws Vs. Traditional Screws

A self-tapping screw is a type of screw that can tap its own hole as it is being driven into the material. This means that self-tapping screws can create their own internal thread as they are installed, without the need for a pre-drilled hole. This feature makes them well-suited for a variety of applications and sets them apart from traditional screws.

Differences In Application

Self-tapping screws are designed for use in materials that may not be suitable for traditional screws. They are commonly used in metal, plastic, and wood, where they can create their own threads without the need for a pre-drilled hole. Traditional screws, on the other hand, require a pre-drilled hole to be used effectively.

When To Choose Self Tapping

Self-tapping screws should be chosen when working with materials that are difficult to tap with traditional screws. They are ideal for applications where a pre-drilled hole is not feasible or when you need to save time and effort by avoiding the extra step of drilling pilot holes. Additionally, self-tapping screws are suitable for situations where disassembly and reassembly may be necessary, as they can maintain their holding power even after multiple uses.

Credit: en.wikipedia.org

Potential Drawbacks

A self-tapping screw offers numerous benefits, but it’s important to be aware of the potential drawbacks associated with its use. Understanding these drawbacks can help in making informed decisions when choosing the right fastening solution for a specific application.

Thermal Damage Risks

When using self-tapping screws, there is a risk of thermal damage during the drilling of the pilot hole. This can be particularly concerning in sensitive applications where thermal damage could compromise the integrity of the material or lead to undesirable consequences. It’s essential to consider the potential for thermal damage and take necessary precautions to mitigate this risk when utilizing self-tapping screws.

Issues With Nonunion And Loosening

Another drawback of self-tapping screws is the possibility of nonunion and loosening of the hardware over time. Improper installation or inadequate torque can contribute to these issues, which can ultimately affect the stability and reliability of the fastened components. Proper training and adherence to recommended installation practices are crucial in minimizing the risk of nonunion and loosening when using self-tapping screws.

Installation Tips

A self-tapping screw is designed to create its own hole while being driven into the material. These screws are ideal for softer materials, such as metal, as they have sharp points and threads that cut into the surface like knives.

Installation TipsWhen it comes to installing self-tapping screws, there are a few tips to keep in mind to achieve optimal fastening. In this section, we will discuss whether to pre-drill or not, and how to ensure you achieve optimal fastening.To Pre-Drill or NotSelf-tapping screws are designed to tap their own hole as they are driven into the material. However, depending on the material you are working with, you may need to pre-drill a pilot hole to prevent the material from splitting or cracking. It is recommended to pre-drill when working with hardwoods, plastics, and metals that are thicker than the screw’s diameter.Achieving Optimal FasteningTo achieve optimal fastening, it is essential to use the correct size and type of self-tapping screw for the job. The screw’s length should be long enough to penetrate the material and provide a secure hold. It is also crucial to ensure that the threads of the screw are fully engaged in the material to prevent the screw from loosening over time.Additionally, it is essential to use the correct driver bit to prevent stripping the screw’s head. A driver bit that fits the screw’s head snugly will prevent slippage and ensure the screw is driven in straight.In conclusion, self-tapping screws are a versatile fastening option that can be used on a wide range of materials. By following these installation tips, you can ensure that your self-tapping screws provide a secure and long-lasting hold.

Credit: bdnfasteners.com

Selecting The Right Screw For Your Diy Project

A self-tapping screw is unique as it can create its own hole while being screwed into the material. This type of screw is ideal for softer materials and sheet metals, making it a versatile choice for various DIY projects. The sharp point and threads act like knives, effortlessly cutting into different mediums.

Material Considerations

A self-tapping screw is designed to create its own hole as it is driven into the material, making it ideal for various DIY projects. When selecting a self-tapping screw for your project, consider the type of material you will be working with. Metal surfaces require different screws than wood or plastic materials.

Screw Tip And Thread Selection

Another crucial aspect to consider when choosing a self-tapping screw is the tip and thread design. For metal surfaces, opt for screws with sharp points and threads that act like knives to cut through the material. On the other hand, for wood or plastic, screws with a different thread pattern may be more suitable.

Common Uses And Applications

Self-tapping screws are versatile fasteners that can tap their own hole as they are driven into various materials. These screws are commonly used in a wide range of applications, both in home DIY projects and industrial settings.

Home Diy Projects

In home DIY projects, self-tapping screws find numerous applications due to their ease of use and effectiveness. Some common uses of self-tapping screws in DIY projects include:

- Assembling furniture

- Hanging shelves or cabinets

- Fixing metal or plastic fixtures

- Repairing appliances

Industrial Applications

Self-tapping screws play a crucial role in various industrial applications where secure and efficient fastening is essential. These screws are widely used in industries such as:

- Automotive manufacturing

- Aerospace engineering

- Construction

- Electronics assembly

Maintaining And Removing Self Tapping Screws

Best Practices

When maintaining self-tapping screws, ensure they are clean and free from debris to prevent issues during installation.

Troubleshooting Common Issues

If encountering resistance when removing self-tapping screws, apply lubricant to ease the process.

Frequently Asked Questions

What Is The Purpose Of Self Tapping Screws?

The purpose of self-tapping screws is to create their own hole while being driven into materials like metal, wood, or plastic. These screws have sharp points and threads that act like knives, cutting into the material as they are screwed in.

What Is The Difference Between A Self-tapping Screw And A Normal Screw?

A self-tapping screw is a type of screw that can create its own hole as it is driven into a material, while a normal screw requires a pre-drilled hole. Self-tapping screws have sharp threads that act like knives cutting into the material, making them ideal for use on metal, wood, and plastic.

They eliminate the need for a pilot hole, saving time and effort during installation.

What Is The Disadvantage Of Self Tapping Screws?

The disadvantage of self-tapping screws is that they require drilling of a pilot hole, which can cause thermal damage and potential issues like infection, hardware loosening, and nonunion.

Do You Need To Pre-drill For Self-tapping Screws?

Yes, self-tapping screws do not require pre-drilling as they can create their own holes while being driven.

Conclusion

Self-tapping screws are versatile fasteners that create their own threads. They are ideal for use in metal, wood, and plastic materials. These screws eliminate the need for pre-drilling and are essential for various applications. Understanding the differences between self-tapping and traditional screws can help in choosing the right fastener for your projects.